石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语试卷1(试题)

说明:1.允许使用中英文字典。 2.原则上 中文题用中文回答,英文题用英文回答 3.选修小语种的同学可不做英语题,但须作附加题。 、填空(每小题0.5分,共计10分。其中,中英文各选填10题) 1.Dairy Products include 2 Types of single effect evaporators of milk include 3.腌腊制品的腌制方法分为 三种方法, 4.传统肉脯的工艺流程主要包括原料肉的选择与整理 二、名词解释释(每小题1.0分,共计4分。其中,中英文各2题) 3.冷却肉 4.腊肠 三、简述题(每小题7分,共计42分。其中,中英文各3题) 1.What is the Stoke's Law 2.What is the Batch method of Pasteurization of milk? 3.What is Recombined Milk? 4.肉类罐头的加工工艺 5.肉松的加工工艺。 6.原料肉变质的原因及变化。 四、论述题(每小题12分,共计24分。其中,中英文各1题) How to produce Stirred style yogurt 2.试述成型火腿的加工工艺及质量控制方法。 五、英翻汉(20分) Cheese:Traditionally,cheese was made as a way of preserving the nutrients of milk. In a simple definition,cheese is the fresh or ripened product obtained after

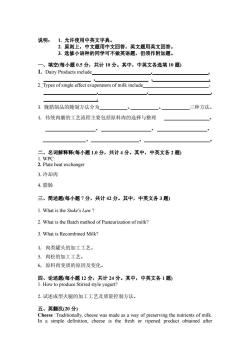

说明: 1. 允许使用中英文字典。 2. 原则上,中文题用中文回答,英文题用英文回答。 3. 选修小语种的同学可不做英语题,但须作附加题。 一、填空(每小题 0.5 分,共计 10 分。其中,中英文各选填 10 题) 1. Dairy Products include , , , , . 2. Types of single effect evaporators of milk include , , , , . 3. 腌腊制品的腌制方法分为 、 、 三种方法。 4. 传统肉脯的工艺流程主要包括原料肉的选择与整理 、 、 、 、 、 、 。 二、名词解释释(每小题 1.0 分,共计 4 分。其中,中英文各 2 题) 1. WPC: 2. Plate heat exchanger 3.冷却肉 4.腊肠 三、简述题(每小题 7 分,共计 42 分。其中,中英文各 3 题) 1. What is the Stoke's Law ? 2. What is the Batch method of Pasteurization of milk? 3. What is Recombined Milk? 4. 肉类罐头的加工工艺。 5. 肉松的加工工艺。 6. 原料肉变质的原因及变化。 四、论述题(每小题 12 分,共计 24 分。其中,中英文各 1 题) 1. How to produce Stirred style yogurt? 2.试述成型火腿的加工工艺及质量控制方法。 五、英翻汉(20 分) Cheese :Traditionally, cheese was made as a way of preserving the nutrients of milk. In a simple definition, cheese is the fresh or ripened product obtained after

coagulation and whey separation of milk,cream or partly skimmed milk,buttermilk or a mixture of these products.It is essentially the product of selective concentration of milk.Thousands of varieties of cheeses have evolved that are characteristic of various regions of the world. Some common cheesemaking steps will be outlined here.Also included is a documen entitled Making Cheese at Home,which includes some helpful references,several cheese making procedures and information about sourcing cheese making supplies Tre ent of Milk on and Milk Ripening .Coagulation enzyme acid o heat-acid ·Curd Treatment ·Cheese Ripening Treatment of Milk for Cheesemaking Like most dairy products. cheesemilk must first be clarified,separated and stand r milk may then be sul ecte Ito a sub-pasteuriz C for 15 to 16 se This therm zation tre ent results in a reduction of high a counts steu While HTST 0° (72 ult in a be er final f d the che e must be sto e by P ed for 60 dav similar to the regulations for raw milk chee Homogenization is not usually done for most cheesemilk.It disrupts the fat globules and increases the fat surface area where casein particles adsorb.This reults in a soft, weak curd at renneting and increased hydrolytic rancidity. Additives The following may all be added to the cheese milk: ·Calcium choride our 。 nydrogen peroxide Caleium choride is added to replace calcium redistributed during pasteurization.Milk coagulation by rer net duri making quires an ontimum halance amond ionic calcium and both soluble insoluble calcium phosphate salts.Because calcium phosphates have reverse solubility with respect to temperature,the heat treatment from pasteurization causes the equilibrium to shift towards insoluble forms and depletes both soluble calcium phosphates and ionic calcium.Near normal equilibrium

coagulation and whey separation of milk, cream or partly skimmed milk, buttermilk or a mixture of these products. It is essentially the product of selective concentration of milk. Thousands of varieties of cheeses have evolved that are characteristic of various regions of the world. Some common cheesemaking steps will be outlined here. Also included is a document entitled Making Cheese at Home, which includes some helpful references, several simple cheese making procedures and information about sourcing cheese making supplies. • Treatment of Milk • Additives • Inoculation and Milk Ripening • Coagulation o enzyme o acid o heat-acid • Curd Treatment • Cheese Ripening Treatment of Milk for Cheesemaking Like most dairy products, cheesemilk must first be clarified, separated and standardized. The milk may then be subjected to a sub-pasteurization treatment of 63-65° C for 15 to 16 sec. This thermization treatment results in a reduction of high initial bacteria counts before storage. It must be followed by proper pasteurization. While HTST pasteurization (72° C for 16 sec) is often used, an alternative heat treatment of 60° C for 16 sec may also be used. This less severe heat treatment is thought to result in a better final flavour cheese by preserving some of the natural flora. If used, the cheese must be stored for 60 days prior to sale, which is similar to the regulations for raw milk cheese. Homogenization is not usually done for most cheesemilk. It disrupts the fat globules and increases the fat surface area where casein particles adsorb. This reults in a soft, weak curd at renneting and increased hydrolytic rancidity. Additives The following may all be added to the cheese milk: • Calcium choride • nitrates • colour • hydrogen peroxide • lipases Calcium choride is added to replace calcium redistributed during pasteurization. Milk coagulation by rennet during cheese making requires an optimum balance among ionic calcium and both soluble insoluble calcium phosphate salts. Because calcium phosphates have reverse solubility with respect to temperature, the heat treatment from pasteurization causes the equilibrium to shift towards insoluble forms and depletes both soluble calcium phosphates and ionic calcium. Near normal equilibrium

is restored during 24-48 hours of cold storage,but cheese makers can't wait that long. so CaCl2 is added to restore ionic calcium and improve rennetability.The calcium assists in coagulation and reduces the amount of rennet required. Sodium or potassium nitrate is added to the milk to control the undesirable effects I Clostria n tyroburyricum in cheeses such as Edam,Gouda,and Swiss Because milk colour of the cheese throughout the year.Annato.Beta-carotene.and paprika are 六.附加题(仅选修小语种的同学完成,共计60分) 1.试述速溶奶粉的加工原理和质量控制方法。(13分) 2.试述搅拌型酸奶的加工工艺和质量控制方法。(13分) 3.简述牛奶杀菌的方法、设备及其工艺参数。(13分) 4.为什么牛奶的酸度是用T度而不用pH表示?(13分) 5.名词解释(每小题2分,共计8分) (1)稀奶油 (2)母发酵剂 (3)原料乳的标准化 (4)益生菌

is restored during 24 - 48 hours of cold storage, but cheese makers can't wait that long, so CaCl2 is added to restore ionic calcium and improve rennetability. The calcium assists in coagulation and reduces the amount of rennet required. Sodium or potassium nitrate is added to the milk to control the undesirable effects of Clostridium tyrobutyricum in cheeses such as Edam, Gouda, and Swiss. Because milk colour varies from season to season, colour may added to standardize the colour of the cheese throughout the year. Annato, Beta-carotene, and paprika are used. 六. 附加题(仅选修小语种的同学完成,共计 60 分) 1. 试述速溶奶粉的加工原理和质量控制方法。(13 分) 2. 试述搅拌型酸奶的加工工艺和质量控制方法。(13 分) 3. 简述牛奶杀菌的方法、设备及其工艺参数。(13 分) 4. 为什么牛奶的酸度是用 T 度而不用 pH 表示?(13 分) 5. 名词解释(每小题 2 分,共计 8 分) (1) 稀奶油 (2) 母发酵剂 (3) 原料乳的标准化 (4) 益生菌

按次数下载不扣除下载券;

注册用户24小时内重复下载只扣除一次;

顺序:VIP每日次数-->可用次数-->下载券;

- 《畜产品加工工艺学》课程教学资源(文献资料)CAC畜产加工标准条目.pdf

- 《畜产品加工工艺学》课程教学资源(文献资料)畜产品可追溯系统的应用现状.pdf

- 石河子大学:《畜产品加工工艺学》课程授课教案(任课教师:卢士玲).pdf

- 石河子大学:《畜产品加工工艺学》课程教学大纲 Technology of Animal Products(负责人:唐明翔).pdf

- 《制茶学》课程教学课件(打印版)第十章 毛茶加工.pdf

- 《制茶学》课程教学课件(打印版)第九章 花茶窨制.pdf

- 《制茶学》课程教学课件(打印版)第八章 红茶初制.pdf

- 《制茶学》课程教学课件(打印版)第七章 青茶初制.pdf

- 《制茶学》课程教学课件(打印版)第六章 白茶.pdf

- 《制茶学》课程教学课件(打印版)第五章 黑茶.pdf

- 《制茶学》课程教学课件(打印版)第四章 黄茶概述.pdf

- 《制茶学》课程教学课件(打印版)第三章 绿茶初制.pdf

- 《制茶学》课程教学课件(打印版)第二章 鲜叶.pdf

- 《制茶学》课程教学课件(打印版)第一章 中国茶叶加工分类.pdf

- 《制茶学》课程实验指导(打印版)实验21 茶叶小包装技术.pdf

- 《制茶学》课程实验指导(打印版)实验20 花茶窨制技术.pdf

- 《制茶学》课程实验指导(打印版)实验19 名茶制作.pdf

- 《制茶学》课程实验指导(打印版)实验18 白茶制造工艺技术.pdf

- 《制茶学》课程实验指导(打印版)实验17 黄茶制造工艺技术.pdf

- 《制茶学》课程实验指导(打印版)实验16 青茶初制系统实验.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语试卷1(答案).pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语试卷2(试题).pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语试卷2(答案).pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产模拟试题1.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产模拟试题2.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产模拟试题3.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产模拟试题4.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产模拟试题5.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语-思考题(试题).pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)畜产-双语-思考题(答案).pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-肉与肉制品-答案.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-肉与肉制品-试题.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-乳与乳制品-试题.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-乳与乳制品-答案.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-蛋制品-答案.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(试卷习题)思考题-蛋制品-试题.pdf

- 石河子大学:《畜产品加工工艺学》课程教学资源(PPT讲稿)第一篇 肉与肉制品 第一章 肉的组成及特性.ppt

- 石河子大学:《畜产品加工工艺学》课程教学资源(PPT讲稿)第一篇 肉与肉制品 第三章 肉的贮藏保鲜.ppt

- 石河子大学:《畜产品加工工艺学》课程教学资源(PPT讲稿)第一篇 肉与肉制品 第二章 畜禽的屠宰及分割.ppt

- 石河子大学:《畜产品加工工艺学》课程教学资源(PPT讲稿)第一篇 肉与肉制品 第七章 干肉制品.ppt