上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 11 Design for Manufacturing

上游充通大 SHANGHAI JIAO TONG UNIVERSITY Design for Manufacturing 福 1日回后

Design for Manufacturing

上游充通大学 e SHANGHAI JIAO TONG UNIVERSITY Product Development Process Concept System-Level Detail Production Planning Testing and Development Design Design Refinement Ramp-Up ☆ ☆☆☆☆☆ How can we emphasize manufacturing issues throughout the development process?

Planning Product Development Process Concept Development System-Level Design Detail Design Testing and Refinement Production Ramp-Up How can we emphasize manufacturing issues throughout the development process?

上游充通大¥ SHANGHAI JIAO TONG UNIVERSITY Design for Manufacturing Example: GM 3.8-liter V6 Engine 380O 及 1日回后

Design for Manufacturing Example: GM 3.8-liter V6 Engine

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY Background information High volumes(3500 engines/ per day) Strong interest in Reducing the cost of the engine Enhancing its quality What? >To improve the air intake manifold (originally made of cast iron) From Product Design and Development by Karl Ulrich and Steven Eppinger (McGraw-Hill/Irwin) One of the most expensive subassemblies in the engine

Background information High volumes (3500 engines / per day) Strong interest in Reducing the cost of the engine Enhancing its quality What? To improve the air intake manifold (originally made of cast iron) • One of the most expensive subassemblies in the engine

上游充通大 SHANGHAI JIAO TONG UNIVERSITY To use composite (redesigned)instead of cast iron ©HoW? >Design for manufacutring From Product Design and Development by Karl Ulrich and Steven Eppinger (McGraw-Hill/Irwin) 1日=后

To use composite (redesigned) instead of cast iron How? Design for manufacutring

上游充通大粤 SHANGHAI JIAO TONG UNIVERSITY Design for X Customer needs and product specifications are for the concept phase Detail design faces the difficulty linking needs and specifications to the specific design issues like: >Reliability Robustness >Serviceablility >Environmental impact Manufacturability Design for X:the X represents one of the above criteria

Design for X Customer needs and product specifications are for the concept phase Detail design faces the difficulty linking needs and specifications to the specific design issues like: Reliability Robustness Serviceablility Environmental impact Manufacturability Design for X: the X represents one of the above criteria

上游充通大¥ SHANGHAI JIAO TONG UNIVERSITY Design for Manufacturing Definition >Design for manufacturing (DFM)is a development practice emphasizing manufacturing issues throughout the product development process. >Successful DFM results in lower production cost without sacrificing product quality

Design for Manufacturing Definition : Design for manufacturing (DFM) is a development practice emphasizing manufacturing issues throughout the product development process. Successful DFM results in lower production cost without sacrificing product quality

上游充通大 SHANGHAI JIAO TONG UNIVERSITY Three Methods to Implement DFM 1.Organization:Cross-Functional Teams In addition to product designers,DFM still needs expertise from: Manufacturing engineers Cost accountants Production personnel 2.Design Rules:Specialized by Firm 3.CAD Tools:Boothroyd-Dewhurst Software >http://www.dfma.com

Three Methods to Implement DFM 1. Organization: Cross-Functional Teams In addition to product designers, DFM still needs expertise from: • Manufacturing engineers • Cost accountants • Production personnel 2. Design Rules: Specialized by Firm 3. CAD Tools: Boothroyd-Dewhurst Software http://www.dfma.com

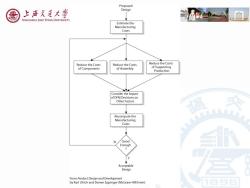

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY Five steps for DFM 1.Estimate the manufacturing costs 2.Reduce the costs of components 3.Reduce the costs of assembly 4.Reduce the costs of supporting production 5.Consider the impact of DFM decisions on other factors

Five steps for DFM 1. Estimate the manufacturing costs 2. Reduce the costs of components 3. Reduce the costs of assembly 4. Reduce the costs of supporting production 5. Consider the impact of DFM decisions on other factors

Proposed 上游充通大学 Design SHANGHAI JIAO TONG UNIVERSITY Estimate the Manufacturing Costs Reduce the Costs Reduce the Costs Reduce the Costs of Components of Assembly of Supporting Production Consider the lmpact of DFM Decisions on Other Factors Recompute the Manufacturing Costs N Good Enough 1 Y Acceptable Design From Product Design and Development by Karl Ulrich and Steven Eppinger(McGraw-Hill/Irwin)

按次数下载不扣除下载券;

注册用户24小时内重复下载只扣除一次;

顺序:VIP每日次数-->可用次数-->下载券;

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 01 Introduction.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Robotics.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Rapid Prototyping.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Quadruped Robots.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Metal cutting.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Machine Tools.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Machine Tools 2.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Introduction to Manufacutring.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_How machine works.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_Engine.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_6shafs.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_5gear.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_4bearings.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_3spring.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_2rivets.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_2Materials&ME.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_1Solid Mechanics.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Technical knowledge_1screw.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Professional knowled_Techcom.pdf

- 上海交通大学:《工程学导论》课程教学资源(讲义)Professional knowled_Project work.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 02 Development Processes and Organizations.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 03 Product Planning.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 04 Identifying Customer Needs.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 05 Product Specifications.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 06 Concept Generation.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 08 Concept Selection.pdf

- 上海交通大学:《工程设计——产品设计与开发 Product Design and Development》课程教学资源(课件讲义,英文版)Chapter 10 Product Architecture.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(作业)HW1.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(作业)HW2.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(作业)HW3.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(作业)HW4.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Course Experiment——Bridge Design.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture 11-1 Safety in Systems Engineering.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture 11-2 Systems Reliability Basics.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture 5 Systems Architecture.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture 9 Effective Innovation in Systems Engineering.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture1 Class Introduction.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture2 Landscape of SE.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture3 Stakeholder Requirements Definition.pdf

- 上海交通大学:《Systems Engineering 系统工程》课程教学资源(电子讲义)Lecture4 Technical Requirement Definition.pdf