西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 6 Lubricating system

Chapter 6 Lubricating system Section 1 Lubricating oil and method The function of the engine lubrication system provides clean lubricating oil to all friction surfaces to reduce friction losses and wear of parts;lubricating oil can cool and clean the worn surface through the lubricating oil circulation;lubricating oil film attached to the part surface can prevent oxidation and corrosion of part; lubricating oil film is formed between the piston,piston rings and the cylinder walls, which can enhance the tightness of the cylinder. Requirements:reasonable oil circuit,reliable operation,ensure engines in all cases that the friction parts can acquire reliable lubrication,and require clean lubricating oil. 1.Lubricating Oil 2.Method of Lubrication According to parts of the working conditions and movement,respectively,the following methods of lubrication. (1)pressure lubrication. (2)splash lubrication. (3)grease lubrication. (4)oil mist lubrication. 械电子工程学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system The function of the engine lubrication system provides clean lubricating oil to all friction surfaces to reduce friction losses and wear of parts; lubricating oil can cool and clean the worn surface through the lubricating oil circulation; lubricating oil film attached to the part surface can prevent oxidation and corrosion of part; lubricating oil film is formed between the piston, piston rings and the cylinder walls, which can enhance the tightness of the cylinder. Requirements: reasonable oil circuit, reliable operation, ensure engines in all cases that the friction parts can acquire reliable lubrication , and require clean lubricating oil. 1. Lubricating Oil 2. Method of Lubrication According to parts of the working conditions and movement, respectively, the following methods of lubrication. (1) pressure lubrication. (2) splash lubrication. (3) grease lubrication. (4) oil mist lubrication. Section 1 Lubricating oil and method

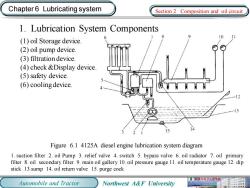

Chapter 6 Lubricating system Section 2 Composition and oil circuit 1.Lubrication System Components (1)oil Storage device. (2)oil pump device. (3)filtration device. (4)check &Display device. (5)safety device. (6)cooling device. Figure 6.1 4125A diesel engine lubrication system diagram 1.suction filter 2.oil Pump 3.relief valve 4.switch 5.bypass valve 6.oil radiator 7.oil primary filter 8.oil secondary filter 9.main oil gallery 10.oil pressure gauge 11.oil temperature gauge 12.dip stick 13.sump 14.oil return valve 15.purge cock 机械持电子工程膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 1. Lubrication System Components (1) oil Storage device. (2) oil pump device. (3) filtration device. (4) check &Display device. (5) safety device. (6) cooling device. Figure 6.1 4125A diesel engine lubrication system diagram 1. suction filter 2. oil Pump 3. relief valve 4. switch 5. bypass valve 6. oil radiator 7. oil primary filter 8. oil secondary filter 9. main oil gallery 10. oil pressure gauge 11. oil temperature gauge 12. dip stick 13.sump 14. oil return valve 15. purge cock Section 2 Composition and oil circuit

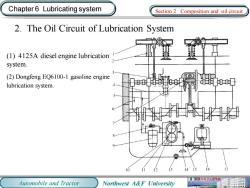

Chapter 6 Lubricating system Section 2 Composition and oil circuit 2.The Oil Circuit of Lubrication System (1)4125A diesel engine lubrication system. (2)Dongfeng EQ6100-1 gasoline engine lubrication system. 0日 斯料仁料 10 机械电子工程学二 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 2. The Oil Circuit of Lubrication System (1) 4125A diesel engine lubrication system. (2) Dongfeng EQ6100-1 gasoline engine lubrication system. Section 2 Composition and oil circuit

Chapter 6 Lubricating system Section 2 Composition and oil circuit (3)6135Q diesel engine lubrication system. 超球好 机被与电子工程保 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system (3) 6135Q diesel engine lubrication system. Section 2 Composition and oil circuit

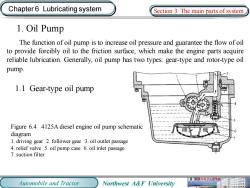

Chapter 6 Lubricating system Section 3 The main parts of system 1.Oil Pump The function of oil pump is to increase oil pressure and guarantee the flow of oil to provide forcibly oil to the friction surface,which make the engine parts acquire reliable lubrication.Generally,oil pump has two types:gear-type and rotor-type oil pump. 1.1 Gear-type oil pump Figure 6.4 4125A diesel engine oil pump schematic diagram 1.driving gear 2.follower gear 3.oil outlet passage 4.relief valve 5.oil pump case 6.oil inlet passage 7.suction filter 业械电子工程学膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 1. Oil Pump The function of oil pump is to increase oil pressure and guarantee the flow of oil to provide forcibly oil to the friction surface, which make the engine parts acquire reliable lubrication. Generally, oil pump has two types: gear-type and rotor-type oil pump. 1.1 Gear-type oil pump Figure 6.4 4125A diesel engine oil pump schematic diagram 1. driving gear 2. follower gear 3. oil outlet passage 4. relief valve 5. oil pump case 6. oil inlet passage 7. suction filter Section 3 The main parts of system

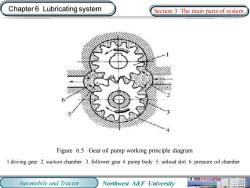

Chapter 6 Lubricating system Section 3 The main parts of system Figure 6.5 Gear oil pump working principle diagram 1.driving gear 2.suction chamber 3.follower gear 4.pump body 5.unload slot 6.pressure oil chamber 析械持电子工程膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system Figure 6.5 Gear oil pump working principle diagram 1.driving gear 2. suction chamber 3. follower gear 4. pump body 5. unload slot 6. pressure oil chamber Section 3 The main parts of system

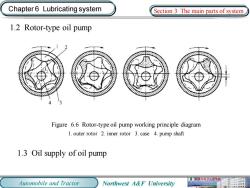

Chapter 6 Lubricating system Section 3 The main parts of system 1.2 Rotor-type oil pump Figure 6.6 Rotor-type oil pump working principle diagram 1.outer rotor 2.inner rotor 3.case 4.pump shaft 1.3 Oil supply of oil pump 械电子工程学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 1.2 Rotor-type oil pump 1.3 Oil supply of oil pump Figure 6.6 Rotor-type oil pump working principle diagram 1. outer rotor 2. inner rotor 3. case 4. pump shaft Section 3 The main parts of system

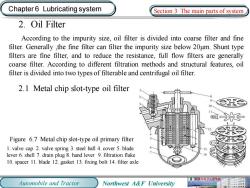

Chapter 6 Lubricating system Section 3 The main parts of system 2.Oil Filter According to the impurity size,oil filter is divided into coarse filter and fine filter.Generally ,the fine filter can filter the impurity size below 20um.Shunt type filters are fine filter,and to reduce the resistance,full flow filters are generally coarse filter.According to different filtration methods and structural features,oil filter is divided into two types of filterable and centrifugal oil filter. 2.1 Metal chip slot-type oil filter 10 Figure 6.7 Metal chip slot-type oil primary filter 1.valve cap 2.valve spring 3.steel ball 4.cover 5.blade lever 6.shell 7.drain plug 8.hand lever 9.filtration flake 10.spacer 11.blade 12.gasket 13.fixing bolt 14.filter axle 机被有电子工程学模 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 2. Oil Filter According to the impurity size, oil filter is divided into coarse filter and fine filter. Generally ,the fine filter can filter the impurity size below 20μm. Shunt type filters are fine filter, and to reduce the resistance, full flow filters are generally coarse filter. According to different filtration methods and structural features, oil filter is divided into two types of filterable and centrifugal oil filter. 2.1 Metal chip slot-type oil filter Figure 6.7 Metal chip slot-type oil primary filter 1. valve cap 2. valve spring 3. steel ball 4. cover 5. blade lever 6. shell 7. drain plug 8. hand lever 9. filtration flake 10. spacer 11. blade 12. gasket 13. fixing bolt 14. filter axle Section 3 The main parts of system

Chapter 6 Lubricating system Section 3 The main parts of system 2.2 Paper filter element coarse(fine)filter Figure 6.8 Paper filter oil coarse filter 1.cover 2.filter sealing ring 3.shell 4.paper filter 5.pallet 6.filter sealing ring 7.tie rod 8.filter pressure spring 9.pressure spring washer 10.tie rod sealing ring 11.shell sealing ring 12.ball valve 13.bypass valve spring 14.sealing washer 15.valve seat 16.sealing washer 17.nut 业电子工程学膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system 2.2 Paper filter element coarse(fine) filter Figure 6.8 Paper filter oil coarse filter 1. cover 2. filter sealing ring 3.shell 4.paper filter 5.pallet 6. filter sealing ring 7. tie rod 8. filter pressure spring 9. pressure spring washer 10. tie rod sealing ring 11. shell sealing ring 12. ball valve 13. bypass valve spring 14. sealing washer 15. valve seat 16. sealing washer 17. nut Section 3 The main parts of system

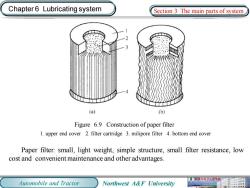

Chapter 6 Lubricating system Section 3 The main parts of system (a) (b) Figure 6.9 Construction of paper filter 1.upper end cover 2.filter cartridge 3.milipore filter 4.bottom end cover Paper filter:small,light weight,simple structure,small filter resistance,low cost and convenient maintenance and other advantages. 机被与电子工程家 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 6 Lubricating system Paper filter: small, light weight, simple structure, small filter resistance, low cost and convenient maintenance and other advantages. Figure 6.9 Construction of paper filter 1. upper end cover 2. filter cartridge 3. milipore filter 4. bottom end cover Section 3 The main parts of system

按次数下载不扣除下载券;

注册用户24小时内重复下载只扣除一次;

顺序:VIP每日次数-->可用次数-->下载券;

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 5 Gasoline fuel supply system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 4 Diesel fuel supply system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 3 Ventilation system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 2 Crank-connecting rod mechanism and parts.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 1 Basic structure and principle of the engine.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Introduction and course overview.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第四章 柴油机燃油供给系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第六章 制动系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第八章 拖拉机汽车动力学.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第五章 转向系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第九章 车辆的使用性能.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第七章 拖拉机动力输出系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第二章 曲柄连杆机构与机体零件.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第三章 联轴器与驱动桥.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)第一章 离合器.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,下册)绪论.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,上册)第十章 发动机的工况与特性.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,上册)第六章 润滑系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,上册)第八章 启动系统、第九章 汽油机点火系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(中文版,上册)第五章 汽油机燃油供给系统.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 7 Engine cooling system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 8 & 9 Starting system & Gasoline ignition system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,上册)Chapter 10 Engine working conditions and features.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Introduction.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 1 Clutch.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 2 Transmission.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 3 Coupling and Drive Axle.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 4 Running system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 5 Steering system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 6 Brake system.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 7 Power takeoff systems of tractors.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 8 Dynamics of vehicles.ppt

- 西北农林科技大学:《汽车拖拉机学》课程PPT教学课件(英文版,下册)Chapter 9 Operational performance of vehicles.ppt

- 华东理工大学:《工程制图》课程教学大纲 Engineering Drawing(负责人:林大匀).pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)前言(编写:刘晶).pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)目录.pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)第一章 点线面.pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)第三章 组合体.pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)第二章 立体.pdf

- 华东理工大学:《工程制图》课程教学资源(学习指导书)第七章 零件图.pdf