上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of single phase alloys(3)

先进材料疑固实验室 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 Solidification of single phase alloys(3) Dr.Mingxu Xia anced Mat 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 Solidification of single phase alloys (3) Dr. Mingxu Xia

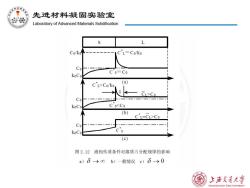

先进材料疑固实验室 Laboratory of Advanced Materials Solidification S L Co/k个 CL=Co/ko Co C s=Co koCo C'LCo C0一 koCo C sCo Co koCo (c) 图2.12液相传质条件对溶质再分配规律的影响 a)6→0b)一般情况c)8→0 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

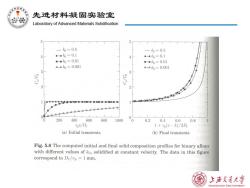

先进材料疑固实验室 Laboratory of Advanced Materials Solidification 5 =0.5 =0.5 ◆◆k=0.1 ◆◆k点=0.1 -而=0.01 ■点=0.01 △4=0.001 △4k=0.001 3 2 -△△△△ 44 0 200 400 600 800 1000 0.2 0.4 0.6 0.8 Vp/De 1+vp(E -L)/2De (a)Initial transients (b)Final transients Fig.5.6 The computed initial and final solid composition profiles for binary alloys with different values of ko,solidified at constant velocity.The data in this figure correspond to De/vp=1 mm. 上浒充通大 SHANGHAI JIAO TONG UNIVERSITY

先进材料疑固实验室 References Laboratory of Advanced Materials Solidification M.C.Flemings,凝固过程 © W.Kurz,凝固原理 ©介万奇,凝固技术 Aavalcer 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

References M.C.Flemings, 凝固过程 W.Kurz,凝固原理 介万奇,凝固技术

先进材料疑固实验室 OUTLINE Laboratory of Advanced Materials Solidification Solute Redistribution Solute distribution coefficient Solute redistribution in equilibrium state Solute redistribution in non-equilibrium state Solute distribution in front of S/L interface Application:Zone melting Morphology Instability of a S/L interface Constitutional undercooling Morphological instability of a S/L interface Solidification microstructure:Cells and dendrites 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

OUTLINE Solute Redistribution • Solute distribution coefficient • Solute redistribution in equilibrium state • Solute redistribution in non-equilibrium state • Solute distribution in front of S/L interface • Application: Zone melting Morphology Instability of a S/L interface • Constitutional undercooling • Morphological instability of a S/L interface • Solidification microstructure: Cells and dendrites

先进材料疑固实验室 Application:Zone melting Laboratory of Advanced Materials Solidification Process of zone melting: Start with a solid alloy bar with uniform cross-section. Place the bar horizontally. Only melt the bar within a short zone with a small heater. Move the heater along the bar from one end to the other end. Repeat the process for many times. y o vancedl Matera 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Application: Zone melting Process of zone melting: • Start with a solid alloy bar with uniform cross-section. • Place the bar horizontally. • Only melt the bar within a short zone with a small heater. • Move the heater along the bar from one end to the other end. • Repeat the process for many times

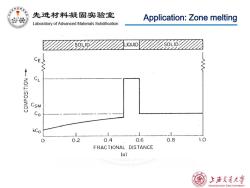

先进材料疑固实验室 Application:Zone melting Laboratory of Advanced Materials Solidification IQUID CE CL CSM kCo 0.2 0.4 0.6 0.8 1.0 FRACTIONAL DISTANCE (a) 上游文通大学 SHANGHAI JIAO TONG UNIVERSITY

Application: Zone melting

先进材料疑固实验室 Application:Zone melting Laboratory of Advanced Materials Solidification Zone melting is a widely used technique for purifying metals. We can derive the equation used to calculate the solute concentration distribution in the solid after the first pass. ©Assumptions: No solute diffusion in the solid Complete solute diffusion and mixing in the liquid zone. 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Application: Zone melting Zone melting is a widely used technique for purifying metals. We can derive the equation used to calculate the solute concentration distribution in the solid after the first pass. Assumptions: • No solute diffusion in the solid • Complete solute diffusion and mixing in the liquid zone

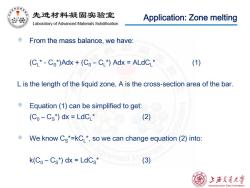

先进材料疑固实验室 Application:Zone melting Laboratory of Advanced Materials Solidification From the mass balance,we have: (CL*-Cs*)Adx+(Co-CL*)Adx ALdCL* (1) L is the length of the liquid zone,A is the cross-section area of the bar. Equation(1)can be simplified to get: (Co-Cs*)dx LdCL* (2) We know Cs*=kCL*,so we can change equation(2)into: k(Co-Cs*)dx LdCs* anced M (3) 上海充通大¥ SHANGHAI JIAO TONG UNIVERSITY

Application: Zone melting From the mass balance, we have: (CL* - CS*)Adx + (C0 – CL*) Adx = ALdCL * (1) L is the length of the liquid zone, A is the cross-section area of the bar. Equation (1) can be simplified to get: (C0 – CS*) dx = LdCL * (2) We know CS*=kCL*, so we can change equation (2) into: k(C0 – CS*) dx = LdCS * (3)

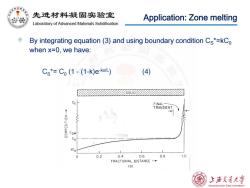

先进材料疑固实验室 Application:Zone melting Laboratory of Advanced Materials Solidification By integrating equation(3)and using boundary condition Cs*=kCo when x=0,we have: Cs*=Co(1-(1-k)e-kx/L) (4) CE FINAL- TRANSIENT CSM Co L 0 0.2 0.4 0.6 0.8 1.0 FRACTIONAL DISTANCE- (b) 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Application: Zone melting By integrating equation (3) and using boundary condition CS*=kC0 when x=0, we have: CS*= C0 (1 - (1-k)e-kx/L) (4)

按次数下载不扣除下载券;

注册用户24小时内重复下载只扣除一次;

顺序:VIP每日次数-->可用次数-->下载券;

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of single phase alloys(2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of single phase alloys(1).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Crystal growth of single element solids 3/3(Crystal growth methods(technology)).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Crystal growth of single element solids 2/3(Crystal growth of single element solids).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Crystal growth of single element solids 1/3(Liquid/solid interface).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Heat flow during the solidification process.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Nucleation in solidification(2/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Nucleation in solidification(1/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Transport phenomena in solidification(2/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Transport phenomena in solidification(1/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Structure and properties of liquid metals(2/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Structure and properties of liquid metals(1/2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Brief of statistic thermodynamics.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Introduction to solidification and casting.pdf

- 上海交通大学:《材料连接原理与工艺》课程教学资源(课件讲稿)第四章 焊接接头的组织和性能.pdf

- 上海交通大学:《材料连接原理与工艺》课程教学资源(课件讲稿)第五章 焊接缺陷.pdf

- 上海交通大学:《材料连接原理与工艺》课程教学资源(课件讲稿)第二章 焊接热过程.pdf

- 上海交通大学:《材料连接原理与工艺》课程教学资源(课件讲稿)第三章 焊接化学冶金.pdf

- 上海交通大学:《材料连接原理与工艺》课程教学资源(课件讲稿)第一章 绪论(芦凤桂).pdf

- 上海交通大学:《材料美学》课程教学资源(课件讲义)隐身与防弹材料(宁月生).pptx

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of single phase alloys(3).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of single phase alloys(3).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of multi phase alloys(1).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of multi phase alloys(2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Solidification of multi phase alloys(2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Metal Casting Technology(1).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Metal Casting Technology(2).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课件讲稿)凝固和铸造 Solidification and casting_Metal Casting Technology(3).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)01. Technology of plasticity——Introduction.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)02. Technology of plasticity——Processing maps.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)03. Technology of plasticity——Elements of plastic theory.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)04. Technology of plasticity——plastic deformation mechanism.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)05. Technology of plasticity——Recovery & recrystallization.pdf

- 《材料加工原理 Principles of Materials Processing》课程教学资源(书籍文献)《Mechanical Metallurgy》(Dieter 1988,SI Metric Edition).pdf

- 《材料加工原理 Principles of Materials Processing》课程教学资源(书籍文献)《Metal Forming Mechanics and Metallurgy》William F. Hosford and Robert M(FOURTH EDITION).pdf

- 《材料加工原理 Principles of Materials Processing》课程教学资源(书籍文献)《RECRYSTALLIZATION AND RELATED ANNEALING PHENOMENA》(SECOND EDITION).pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)金属材料热处理原理 Heat Treatment Principles of Metals Chapter 8 Intro to Phase Transformation in Solids.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)金属材料热处理原理 Heat Treatment Principles of Metals Chapter 8 Intro to Phase Transformation in Solids.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)金属材料热处理原理 Heat Treatment Principles of Metals Chapter 9 Eutectoid and Reverse Eutectoid.pdf

- 上海交通大学:《材料加工原理 Principles of Materials Processing》教学资源(课程讲稿)金属材料热处理原理 Heat Treatment Principles of Metals Chapter 9 Eutectoid and Reverse Eutectoid.pdf