《纺织复合材料》课程参考文献(Composite materials design and applications)19 APPENDIX 1

APPENDIX 1 STRESSES IN THE PLIES OF A LAMINATE OF CARBON/EPOXY LOADED IN ITS PLANE The tables in this appendix give for each ply in the laminate the stresses along the principal orthotropic directions of the ply,denoted as e and t.These stresses are denoted as o,o,,Ta.The laminate is successively subjected to three cases of simple loading: o=1 MPa:normal stress along the 0 direction. o,=1 MPa:normal stress along the 90 direction. Txy=1 MPa:shear stress. CHARACTERISTICS OF EACH PLY V=60%fiber volume fraction. Thickness of each ply:0.13 mm. ■Moduli: Modulus along the fiber direction:E=134,000 MPa. Modulus along the transverse direction:E,7000 MPa. Shear modulus:Ga =4200 MPa. Poisson coefficient:v=0.25. ■ Fracture strength: Tension along the longitudinal direction:nupure=1270 MPa. Compression along the longitudinal direction:pure=1130 MPa. Tension along the transverse direction:,pue=42 MPa. Compression along the transverse direction:o,upure=141 MPa. Shear strength:a nupure=63 MPa. 2003 by CRC Press LLC

APPENDIX 1 STRESSES IN THE PLIES OF A LAMINATE OF CARBON/EPOXY LOADED IN ITS PLANE The tables in this appendix give for each ply in the laminate the stresses along the principal orthotropic directions of the ply, denoted as and t. These stresses are denoted as σ, σt , τ t . The laminate is successively subjected to three cases of simple loading: σx = 1 MPa: normal stress along the 0° direction. σy = 1 MPa: normal stress along the 90° direction. τ xy = 1 MPa: shear stress. CHARACTERISTICS OF EACH PLY Vf = 60% fiber volume fraction. Thickness of each ply: 0.13 mm. Moduli: Modulus along the fiber direction: E = 134,000 MPa. Modulus along the transverse direction: Et = 7000 MPa. Shear modulus: Gt = 4200 MPa. Poisson coefficient: νt = 0.25. Fracture strength: Tension along the longitudinal direction: σ rupture = 1270 MPa. Compression along the longitudinal direction: σ rupture = 1130 MPa. Tension along the transverse direction: σt rupture = 42 MPa. Compression along the transverse direction: σt rupture = 141 MPa. Shear strength: τ t rupture = 63 MPa. TX846_Frame_Appendix Page 503 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC �������������

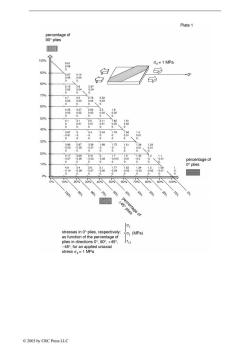

Plate 1 percentage of 90°plies 血 100 品 x=1 MPa 90% 白 品 -0 合 2 80% 70% 。 80 品 50% 4.1 品 211 0.02 82 0 0 40 3.97 .78 6 -0.01 0. 8 00 0.01 0 30% 199 72 15到 8 0.01 0 0. 20% 4.17 2.41 1.5 1.33 2 1.1 0.07 -0.03 -0.02 -0.015 -0.01 - 0.01 0 0. o percentage of 10% 0°plies 品2 100 0. 0% 1096 209 309 40e 509 609 70 80% 909 100 00% 90 80 60% 50% 40 30% 20 10 0% percentage of t4 plies (o: stresses in 0 plies,respectively (MPa) as function of the percentage of plies in directions0°,90°,+45 \a -45,for an applied uniaxial stress oy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 504 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

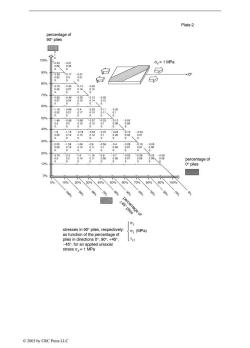

Plate 2 percentage of 9o°plies 1009% Ox=1 MPa 90% 2 0 017 -0 82 89 亡 日: 0.25 0.12 -0.02 0.14 0.12 0. 0 8数 0.11 50%6 149 -0.37 0.23 -0.12 -0.03 015 0.13 01 .09 0.08 0. 0. 0 0. 0 a19 -0.54 -0.37 -0.24 0.13 0.04 0.12 0.09 008 .07 0. 0. 0 0 0 0 0 30% 89 88 0 20% 1.6 1.18 0.9 -0.7 -0.52 0.38 -0.23 -0.08 14 0.11 .09 0.08 .07 0.0 0.08 0.06 10 0. 0. 0 0 0 0 percentage of 0°plies 0%e 0% 10 209 30% 4096 50% 60% 70% 809% 90 100 100% 90% 80% 70 60% 50% 30% 20% 10% percentage of ±45°plies 6 stresses in 90 plies,respectively: (MPa) as function of the percentage of plies in directions0°,9o°,+45°, -45°,for an applied uniaxial stress ox=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 505 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

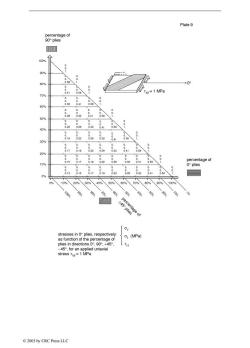

Plate 3 percentage of 90°plies 1009 6.43 Ox=1 MPa 0.41 0.4③ 90% 2.84 白 -0 0.18 -0.34 -02 2.43 1.82 0.16 0.12 0.17 -0.12 2.1 0.13 733 0.09 -0.28 -012 -0.09 889 品8 .04 0.07 0.15 0.09 0.07 -0.16 0.06 品 8 0.7 1小幼 8d 8 0.7 0.85 0.61 0.05 0.04 0.04 004 013 008 -0.07 0.05 0.05 673 0 0.54 05 0.5 0.47 9 0.05 0.04 0.04 0.03 0.03 0.03 0.2 0.15 percentage of 0.11 -0.09 0.08 0.08 0.05 -0.04 0°plies 82 88 0% 0% 10% 20阳 30% 409% 509% 709 809 90% 1009 100% 90 80r 60% 40% 30% 20% percentage ±45°pies 6 stresses in +45 plies,respectively (MPa) as function of the percentage of plies in directions0°,90°,+45° 人心 -45°,for an applied uniaxial stress cy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 506 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 4 percentage of 9o°plies 1009 x=1 MPa 白 -09 宁 甜 品2 品 品。 8 88 0.7 0.05 0.08 8 0.05 鹏 8 88 0.54 0. 0.48 047 88s 88 0.03 0.03 0.06 003 0.15 0.04 percentage of 888 0.4 8 0.28 9 0.25 025 0.25 0°plies 03 0.03 0.02 0.02 0.02 0.02 0.02 0. 0.27 0.19 0.14 0.12 0.1 0.0g 0.07 0.08 0.05 0 0% 10 209 30%a 40% 50% 60% 709% 80% 90% 100% 00% 90 80r% 60% 50% 0% 30% 20% 0 percentage of t4 plies 6 stresses in-45 plies,respectively: G:(MPa) as function of the percentage of plies in directions0°,90°,+45 -45°,for an applied uniaxial stress cx=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 507 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 5 percentage of 90°plies 100 0 90% 023 *0 006 0. 0. 80% 3 -0.16 0.04 8 87 70% ,=1a 889 029 -0.13 0.07 00e 808 0 0. 60% 83e 88 012 09 8e 0. 0. 0 50% 品 3 02 8 8 8 40% 0 037 0.13 8 612 014 o. 0 0 0. 0. 0. 309 -1.6 -1.1 06 04 -028 0.13 4 0.15 810 82 20% 2.2 158 .18 0.87 06 048 0.33 87 -0.01 percentage of 89 8i9 82 82 24 027 0 8 035 0°plies 10 8 0.75 058 -033 037 43 0.52 068 0 0. 0 0 0 0. 0% (o 10% 20% 30% 409% 50% 60% 70% 80% 90% 100% 100% 90% 70% 60% 50% 40% 30% 0% 10% 0% percentage ±45°plies 6 stresses in 0 plies,respectively (MPa) as function of the percentage of plies in directions0°,90°,+45o t -45°,for an applied uniaxial stress oy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 508 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 6 percentage of 90°plies 100 1.09 0 90% 8 *0 0. & 70 ☑,=1wa 。 756 8 62 172 1.78 0.c2 0. 0. 0 190 。8 8 0 40P 0 278 297 002 0.03 0.04 0. 0. 0. 0 309 300 。品 品 38 39明 43 387 percentage of 00 8 0.09 888 0°plies 109 0% 0% 10% 20% 40 50% 60% 709% 09% 90% 100% 100% 90 80 70 60% 50 40% 30% percentage ±45°plies Ge stresses in 90 plies,respectively o,(MPa) as function of the percentage of plies in directions0°,90°,+45° -45°,for an applied uniaxial stress oy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 509 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 7 percentage of 9o°plies 100 8 0 049 80g 品 -1 MPa 0. 88g 8 88 器 品 88 284 percentage of 88 o°plies 翩 2 260 384 482 643 8品 017 025 031 041 024 026 02 034 043 0% 10% 20% 30%6 40% 509% 60% 70% 80% 90a 1009 100% 80% 709 60% 40% % percentage ±45°plies 6 stresses in +45 plies,respectively G,(MPa) as function of the percentage of plies in directions0°,90°.+45 -45°,for an applied uniaxial stress cy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 510 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 8 percentage of 90°plies 100 8 90 028 0.49 *0 % 88 80 Cy 1 MPa 709% 071 82 886 88 085 005 509% 0 0.03 i 0.06 007 0.12 0.09 07 0.07 8 0.61 1.33 0.04 d87 0.08 0.03 14 0.11 0.1 o.ce 0.0g 0.09 -0.0g 11 127 1.43 12 0.07 0.08 0.09 0.1 0.12 02 0.15 0.13 0.12 0.12 0.12 -0.12 0.12 4 i.6 i84 2.11 243 28 percentage of 0.06 008 0 01 012 014 0.18 018 0°plies 0.2 -0.18 -0.18 -0.18 -0.16 -018 -0.17 -0.19 14 2 3.17 3.84 4.82 0.09 0.1 e 5 0.17 0.2 0.31 0.4 05 0.33 -027 025 024 024 D28 02 034 043 09% 0% 10% 209% 30% 409% 50% 60% 706 809. 1009% 100 90% 0 70% 60% 50% 40% 30% 20 percentage ±45°plies f Gt stresses in-45 plies,respectively: (MPa) as function of the percentage of plies in directions0°,90°,+45° -45°,for an applied uniaxial stress o=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 511 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 9 percentage of 90°plies 100% 90% 00, 80% 8 +0 001 Txy=1 MPa 70% 00 60% 0. 60% 6。 0 8 0.22 26 0.32 841 0.58 40% 8。 022 0 001 0.41 30% 0 8 1 20% 0 0 0.15 0.17 0.19 0. 0.26 0.32 0.4 058 percentage of 10% 0°plies 0 0.13 0.15 0.17 0.19 0.22 0.28 0.32 0.41 0.59 0% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 100 80% 70 60% 50% 40 30% 20 10 percentage ±45°pies Ge stresses in 0 plies,respectively c,(MPa) as function of the percentage of plies in directions0°,90°,+45 -45°,for an applied uniaxial stress txy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 512 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

按次数下载不扣除下载券;

注册用户24小时内重复下载只扣除一次;

顺序:VIP每日次数-->可用次数-->下载券;

- 《纺织复合材料》课程参考文献(Composite materials design and applications)18 APPLICATIONS.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)17 FLEXURE OF THICK COMPOSITE PLATES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)16 COMPOSITE BEAMS IN TORSION.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)15 COMPOSITE BEAMS IN FLEXURE.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)14 THE HILL–TSAI FAILURE CRITERION.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)13 ELASTIC COEFFICIENTS.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)12 MECHANICAL BEHAVIOR OF THIN LAMINATED PLATES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)11 ELASTIC CONSTANTS OF A PLY ALONG AN ARBITRARY DIRECTION.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)10 ELASTIC CONSTANTS OF UNIDIRECTIONAL COMPOSITES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)09 ANISOTROPIC ELASTIC MEDIA.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)08 COMPOSITE MATERIALS FOR OTHER APPLICATIONS.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)07 COMPOSITE MATERIALS AND AEROSPACE CONSTRUCTION.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)06 JOINING AND ASSEMBLY.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)05 CONCEPTION AND DESIGN.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)04 SANDWICH STRUCTURES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)03 PLY PROPERTIES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)02 FABRICATION PROCESSES.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)01 COMPOSITE MATERIALS, INTEREST, AND PROPERTIES.pdf

- 《纺织复合材料》课程教学资源(书籍文献)Microstructural Design of Fiber Composites.pdf

- 《纺织复合材料》课程参考文献(3-D textile reinforcements in composite materials)3-D textile reinforcements in composite materials.pdf

- 《纺织复合材料》课程参考文献(Composite materials design and applications)21 BIBLIOGRAPHY.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)01 Introduction and Overview.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)03 Fibers for Polymer-Matrix Composites.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)04 Polymeric Matrix Materials.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)05 Component Form and Manufacture.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)06 Structural Analysis.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)07 Mechanical Property Measurement.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)08 Properties of Composite Systems.pdf

- 《纺织复合材料》课程参考文献(Composite Materials for Aircraft Structures)09 Joining of Composite Structures.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 1 OBJECTIVES.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 2 GUIDELINES FOR PROPERTY TESTING OF COMPOSITES.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 3 EVALUATION OF REINFORCEMENT FIBERS.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 4 MATRIX CHARACTERIZATION.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 5 PREPREG MATERIALS CHARACTERIZATION.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 6 LAMINA, LAMINATE, AND SPECIAL FORM CHARACTERIZATION.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 7 STRUCTURAL ELEMENT CHARACTERIZATION.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)CHAPTER 8 STATISTICAL METHODS.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)Front Matter.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)Index.pdf

- 《纺织复合材料》课程参考文献(Composite Materials Handbook,Volume 1)Standardization Document Improvement Proposal.pdf